Vacuum Media Filters

Vacuum Media Coolant Filtration

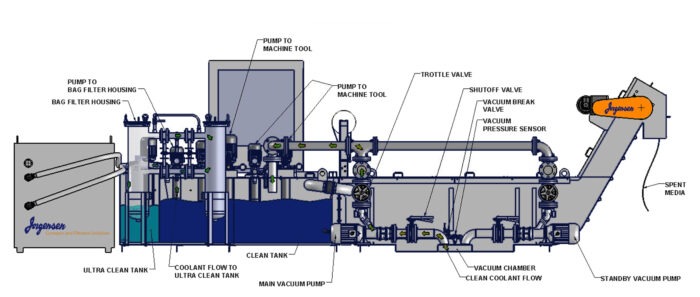

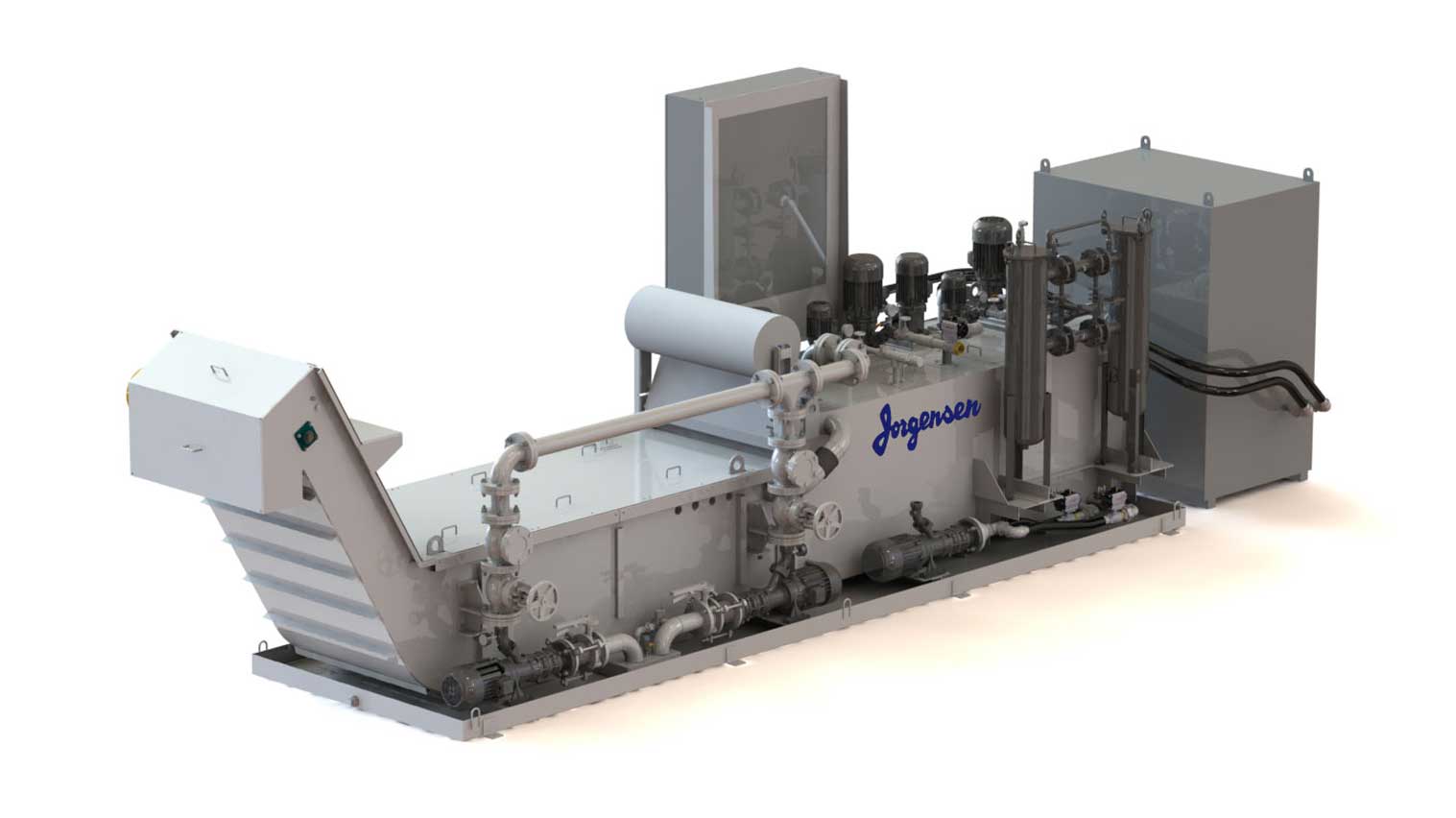

A vacuum filter system removes composite fines, metal chip fines, or grinding swarf to achieve coolant clarity of 25 microns or less. Vacuum filtration excels in high coolant flow rates, over 100 gpm, and in applications machining carbon fiber. They work especially well in aerospace machining applications.

Deep filter cakes provide efficient removal of fine chips, grinding sludge, and swarf for cost-saving coolant use. In cases where ultra-clean coolant is required (high pressure/through spindle), a designated pump transfers clean coolant through bag filters, then into a section of the tank with clarity of 10 microns or less.

Vacuum filtration can function as primary or secondary filtration. All Jorgensen vacuum filters are fabricated with modular filter and tank components for a custom fit. Options such as chillers, tramp oil skimmers, and high-pressure pumps can be added to a vacuum filter.