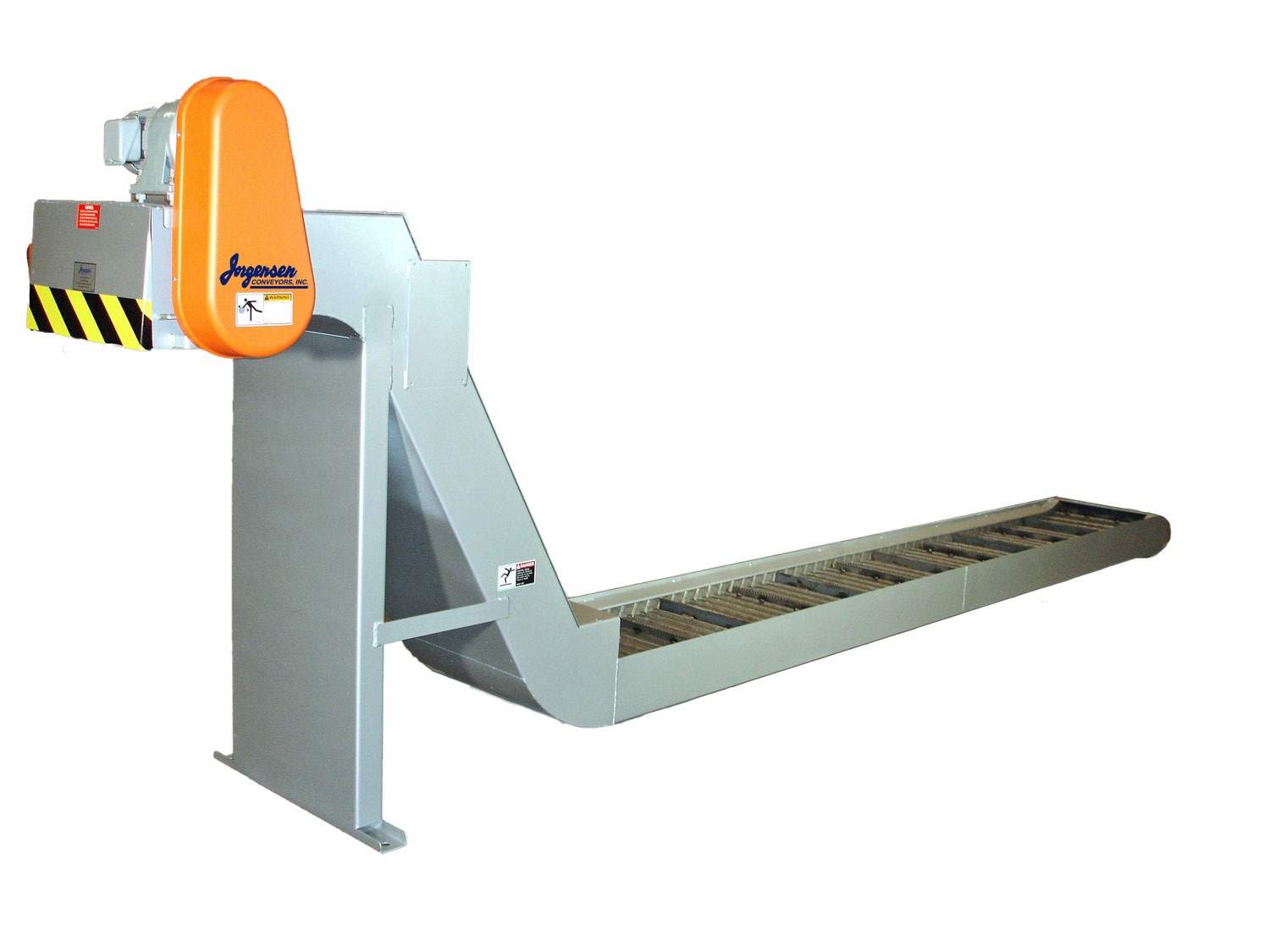

Hinged Steel Belt Conveyor 2.5″ Pitch

Custom Engineered Conveyors and Belting

2.5″ hinged steel belt conveyors are ideal for larger machine tool scrap removal. Their durable, low-profile design makes them ideal for handling small parts, stampings, scrap, chips, or turnings. Design flexibility lets customers choose a wide range of conveyor dimensions. Jorgensen’s completely detachable belt design allows for easy maintenance. Warranty and after-market component parts provide trouble-free operation and support.

Additional coolant reservoirs and tank options are available for machine tool applications using cutting oil and coolant. For further coolant filtration, upgrade hinged steel belt conveyors to EcoFilters, or add FlexFiltration.