Stamping

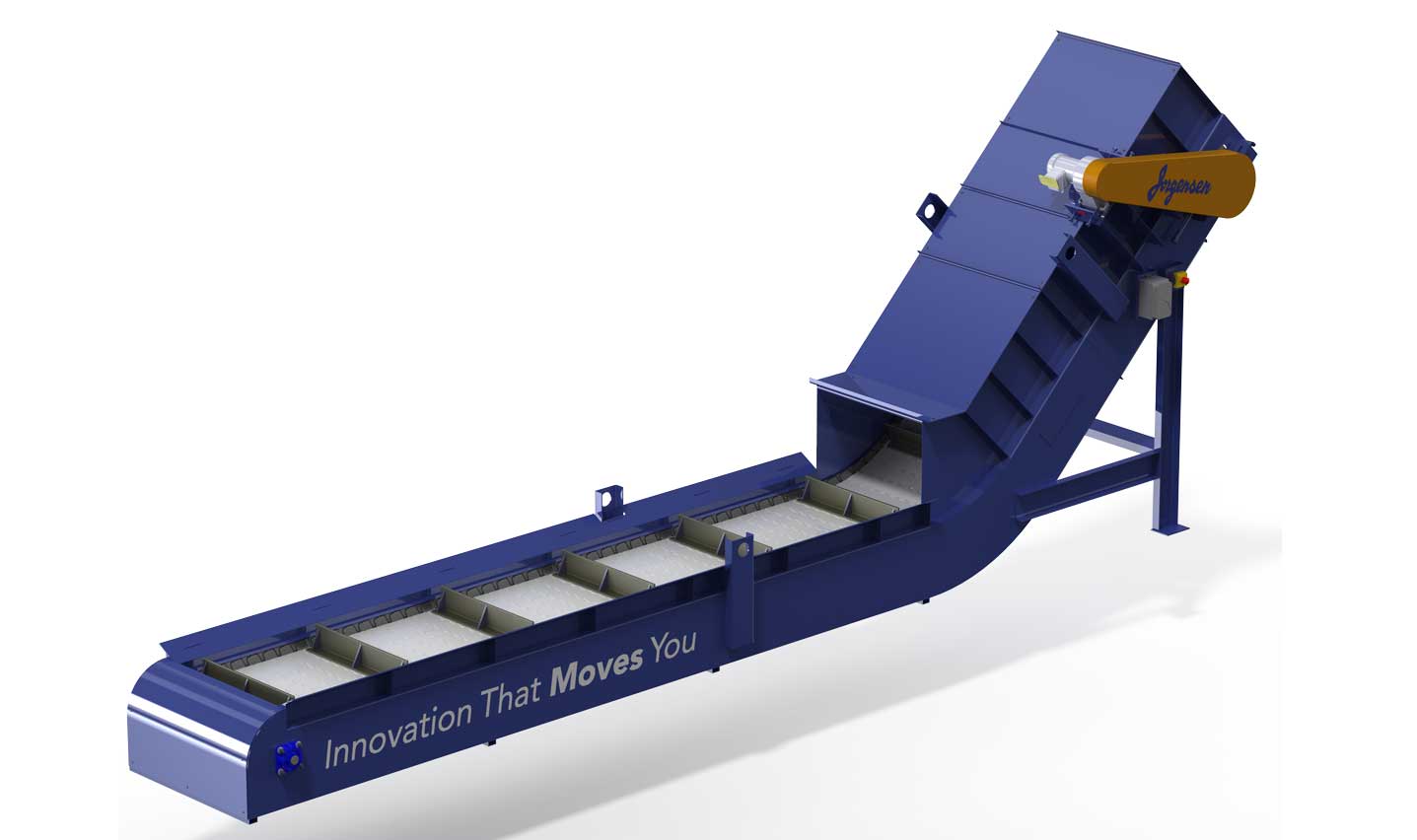

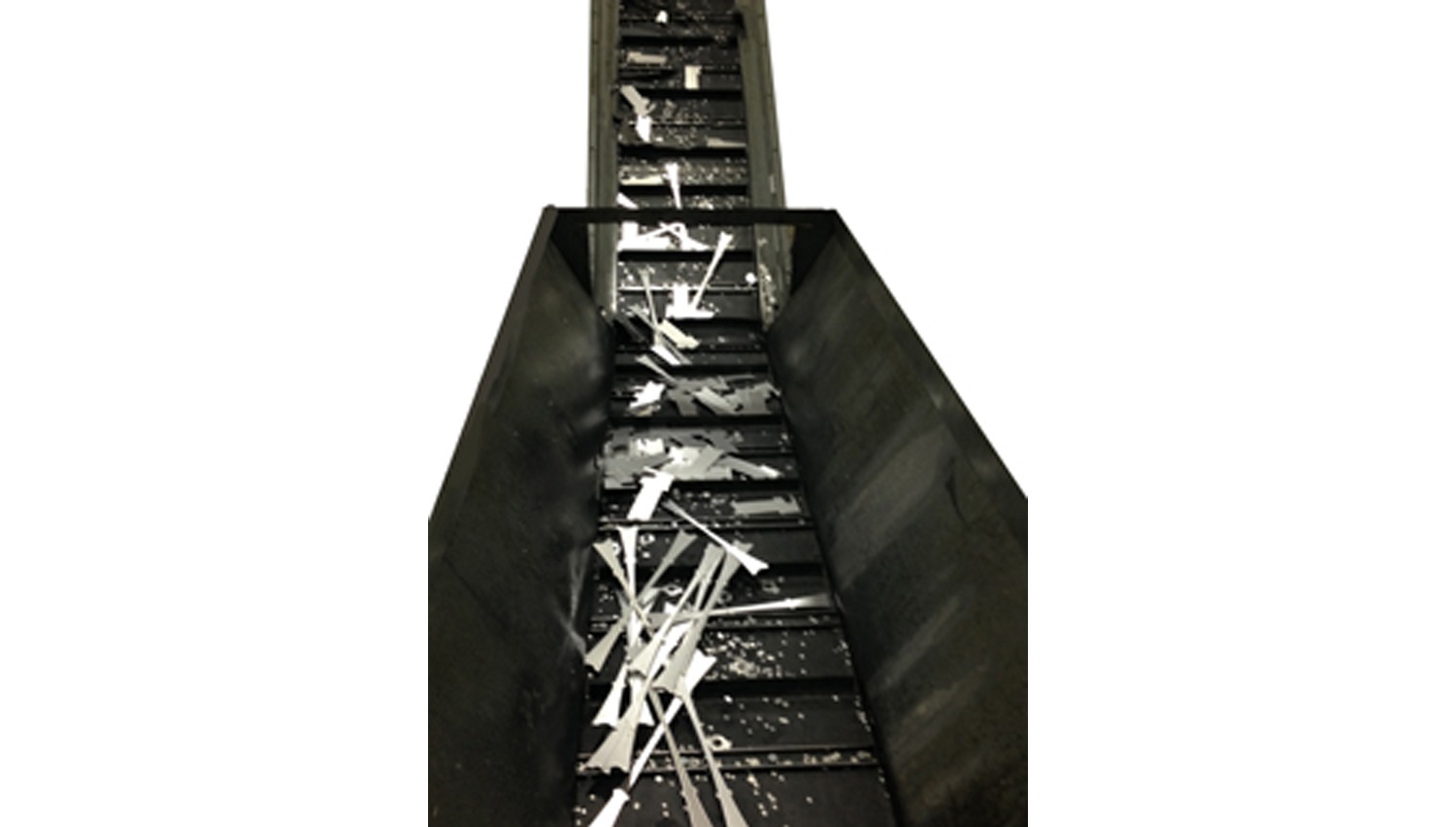

Stamping involves cutting, forming, or shaping metal sheets or blanks using mechanical presses and dies. Jorgensen offers a complete line of engineered conveyor solutions for your stamping application. Stamping scrap can be handled using a variety of conveyor types. Most commonly, hinged steel belt conveyors are used along with magnetic and slider bed conveyors. Our hinged steel belt stamping conveyors incorporate specially designed side wings and hinge loop armor to close the gaps that are typically found on hinged steel belts. These features prevent materials from becoming caught in the belt and jamming the conveyor. Jorgensen recommends the use of pimpled belts for all stamping applications to prevent oily materials from sticking to the belt. We also incorporate various types of clean out areas on the conveyor casing that allow any material that might stick to the belt to fall out, again minimizing the chance of jamming.

Conveyor solutions for stamping applications are critical for efficiently handling and transferring metal sheets or parts through the stamping process. Conveyor systems in stamping applications need to be robust, reliable, and capable of withstanding the heavy loads and fast-paced nature of the stamping process. All of our conveyor products can incorporate state of the art controls and sensor technologies to optimize your stamping scrap handling system’s performance.

For more information on stamping conveyors, check out our article in The Stamping Journal

Contact us to learn how these and other Jorgensen product solutions are made for your application!