Central Systems

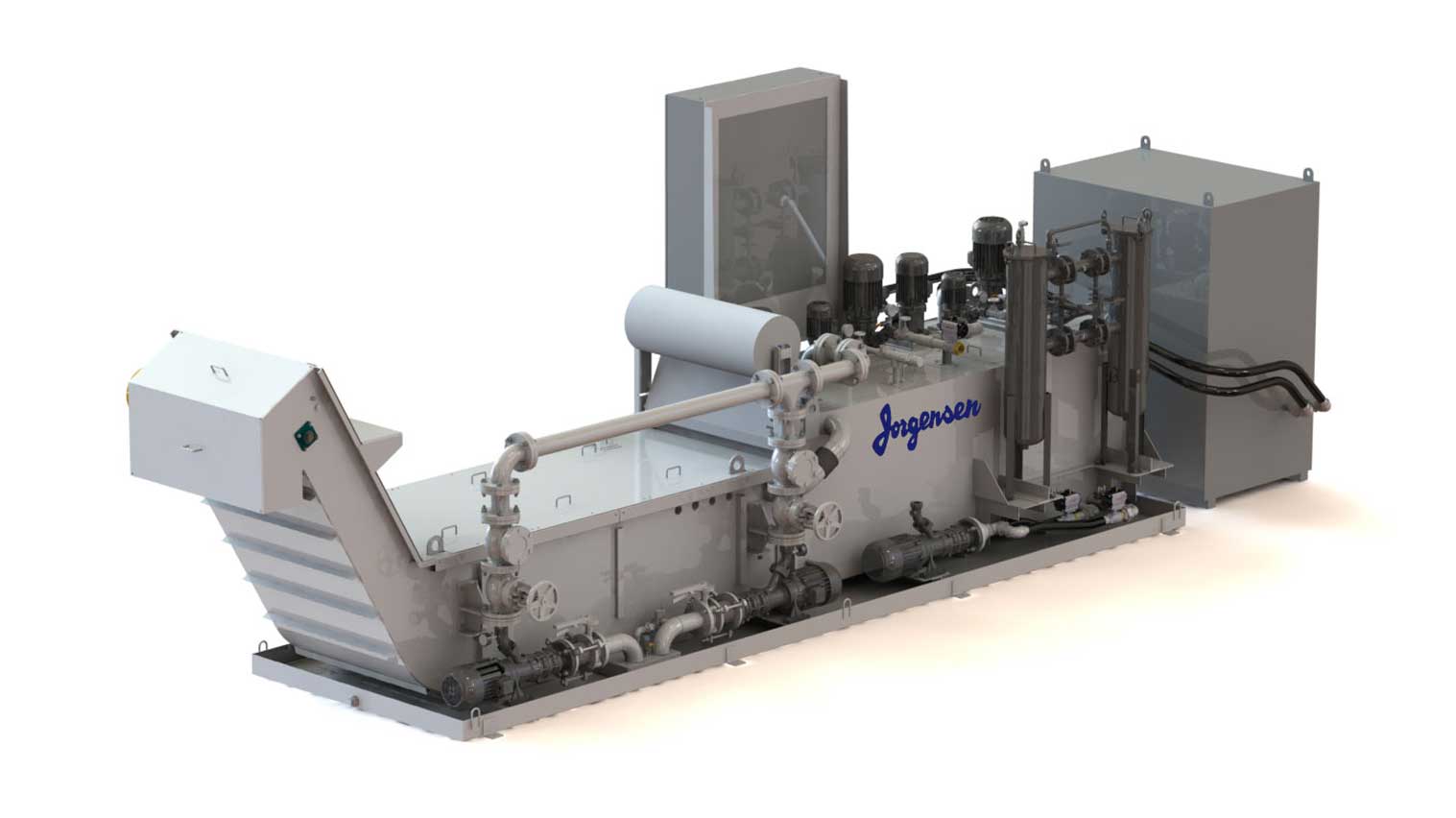

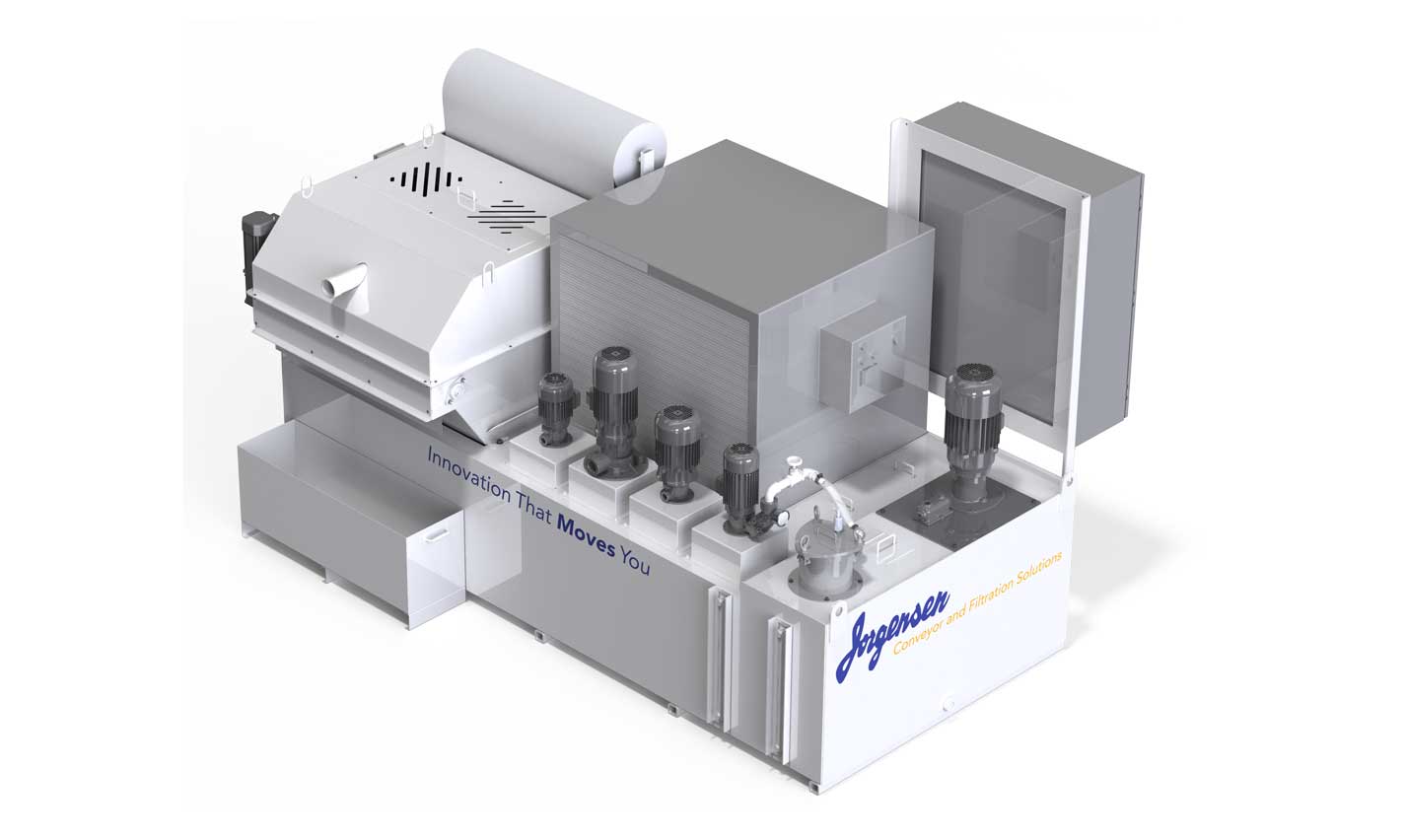

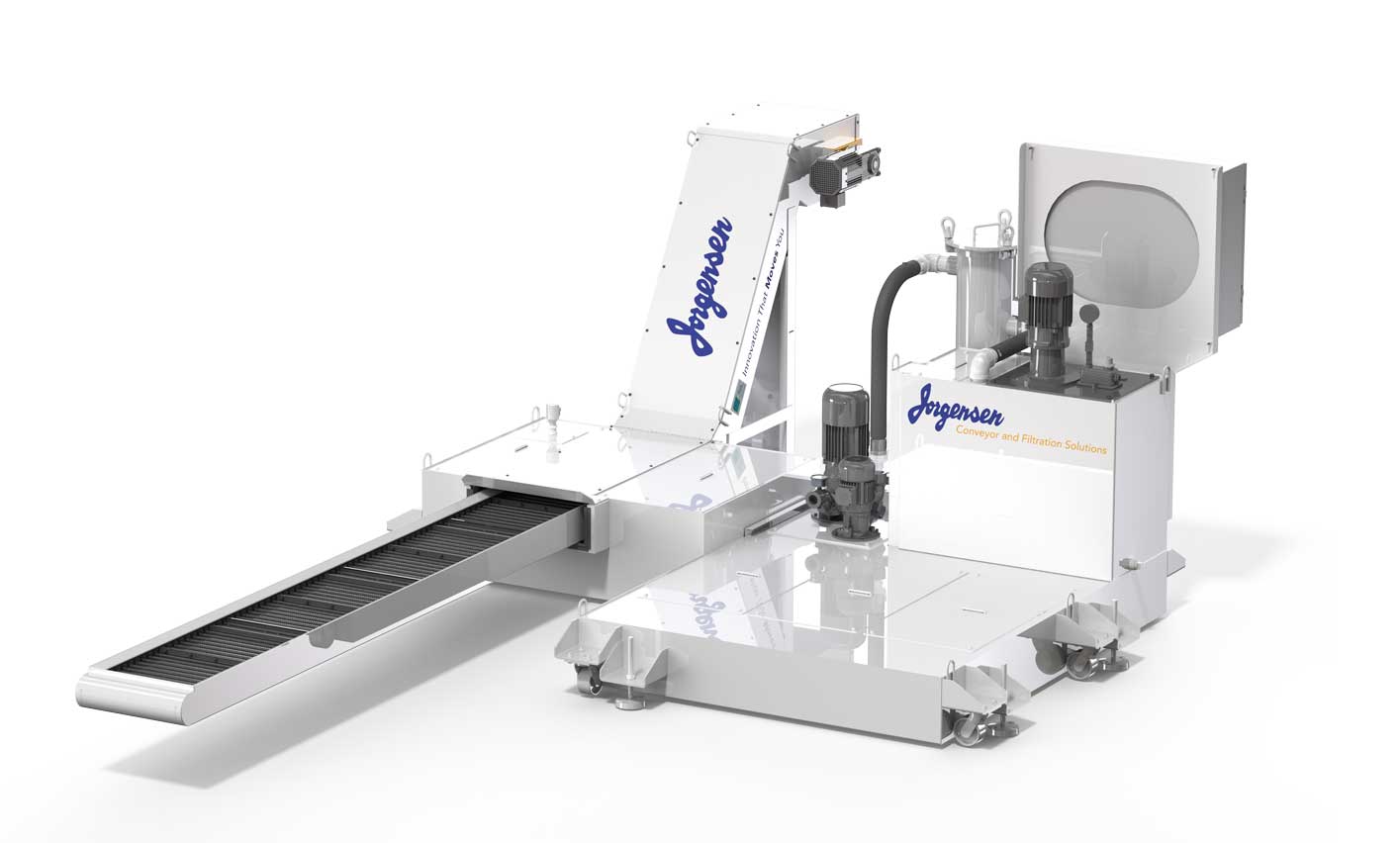

Jorgensen offers a complete line of engineered conveyors and filtration equipment for your Central Coolant Filtration System application. A central coolant system is used in various industrial processes, particularly in metalworking and machining applications, to provide a continuous supply of coolant or cutting fluid to multiple machines or workstations. Conveyors play a critical role in the efficient operation of a central coolant system by transporting coolant between the central reservoir and the individual machine tools.

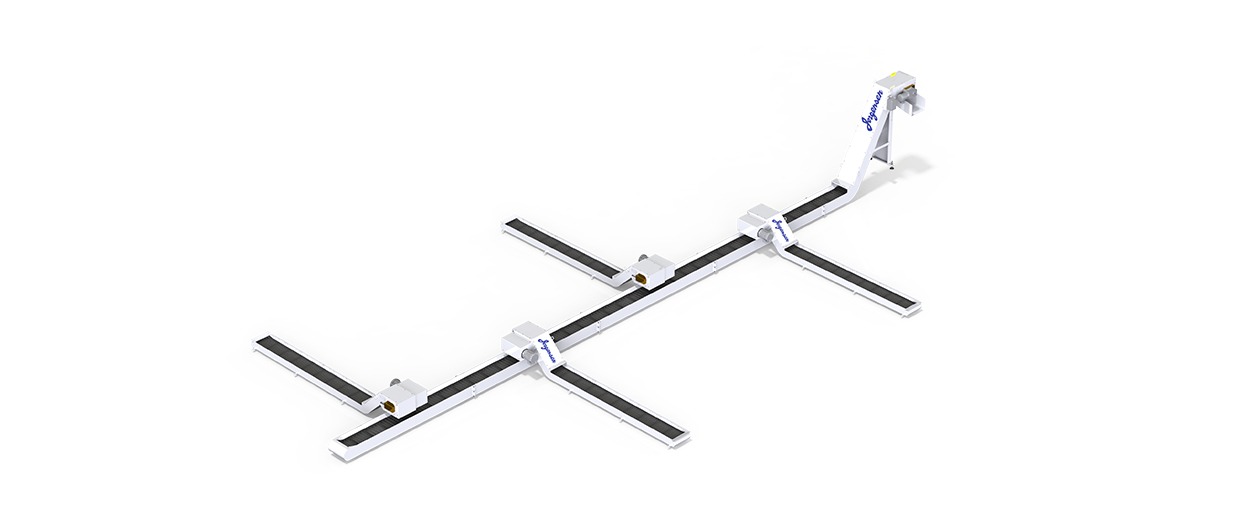

In a Central Chip Collector system, the primary objective is to efficiently collect and transport metal chips and swarf from multiple machine tools to a central collection point for further processing or recycling. Conveyors used in central chip collector systems are designed to handle the flow of metal chips and swarf while minimizing spillage and ensuring smooth and continuous operation.

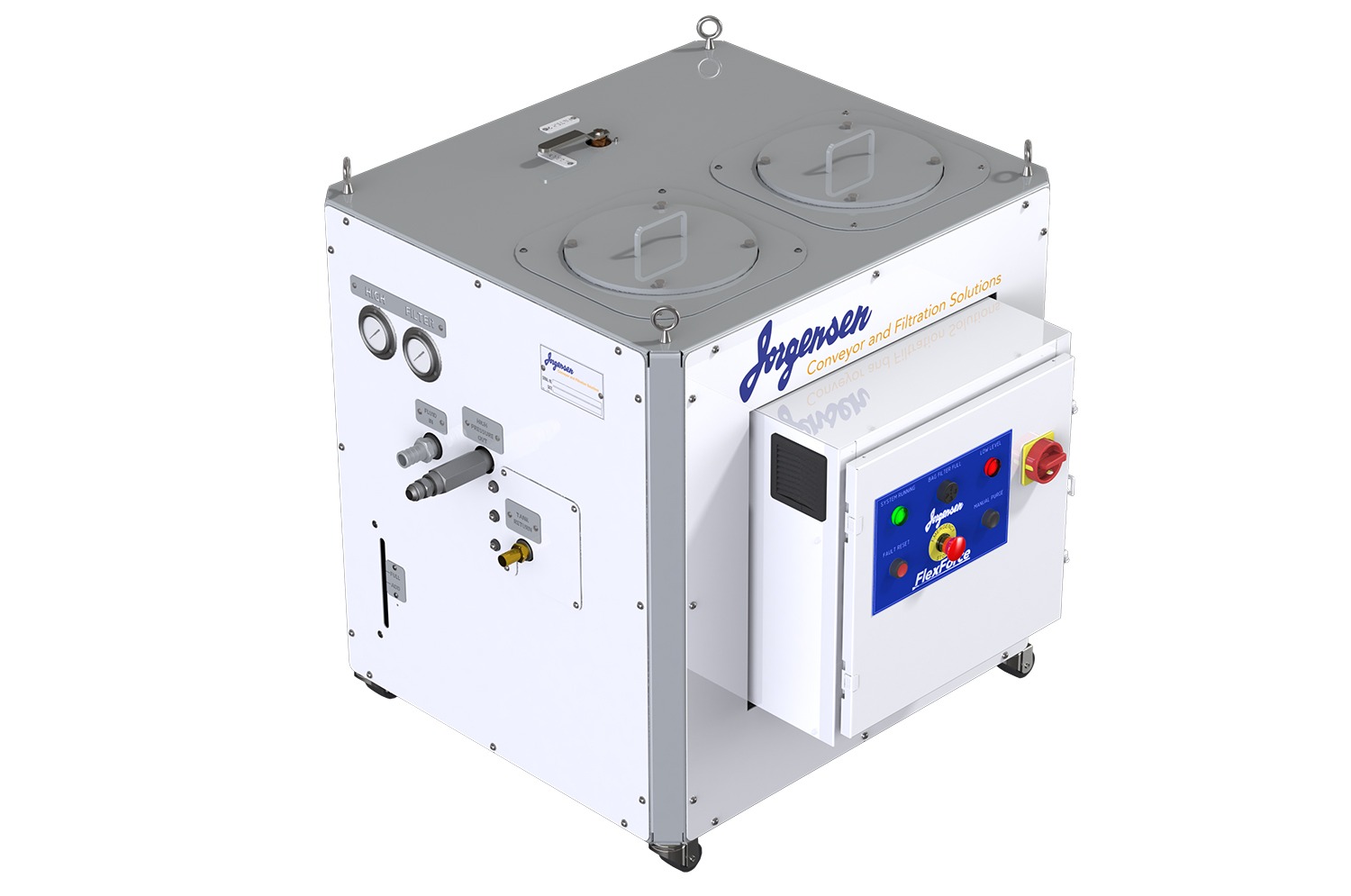

Our engineers will work with you to design a system that will best utilize the space available and keep costs and maintenance to a minimum. These systems can use a wide variety of filter and conveyor types and can be designed to incorporate coolant make-up systems, chillers, tramp oil separators magnetic drums and other accessories to meet your specific requirements. All of our conveyor and filter products can incorporate state of the art controls and various sensor technologies to optimize your central coolant filtration system’s performance.

Contact us to learn how these and other Jorgensen product solutions are made for your application!