Casting

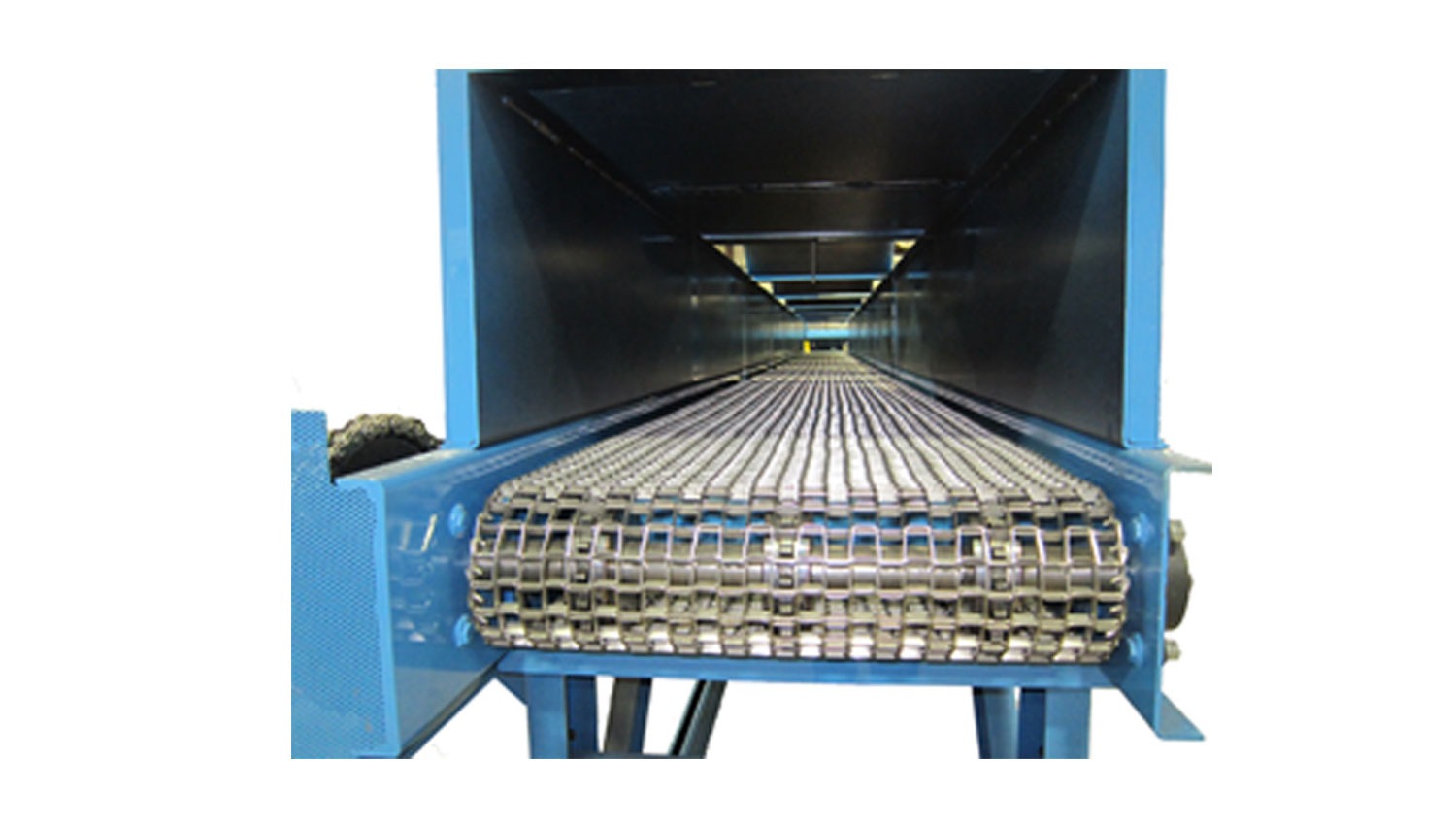

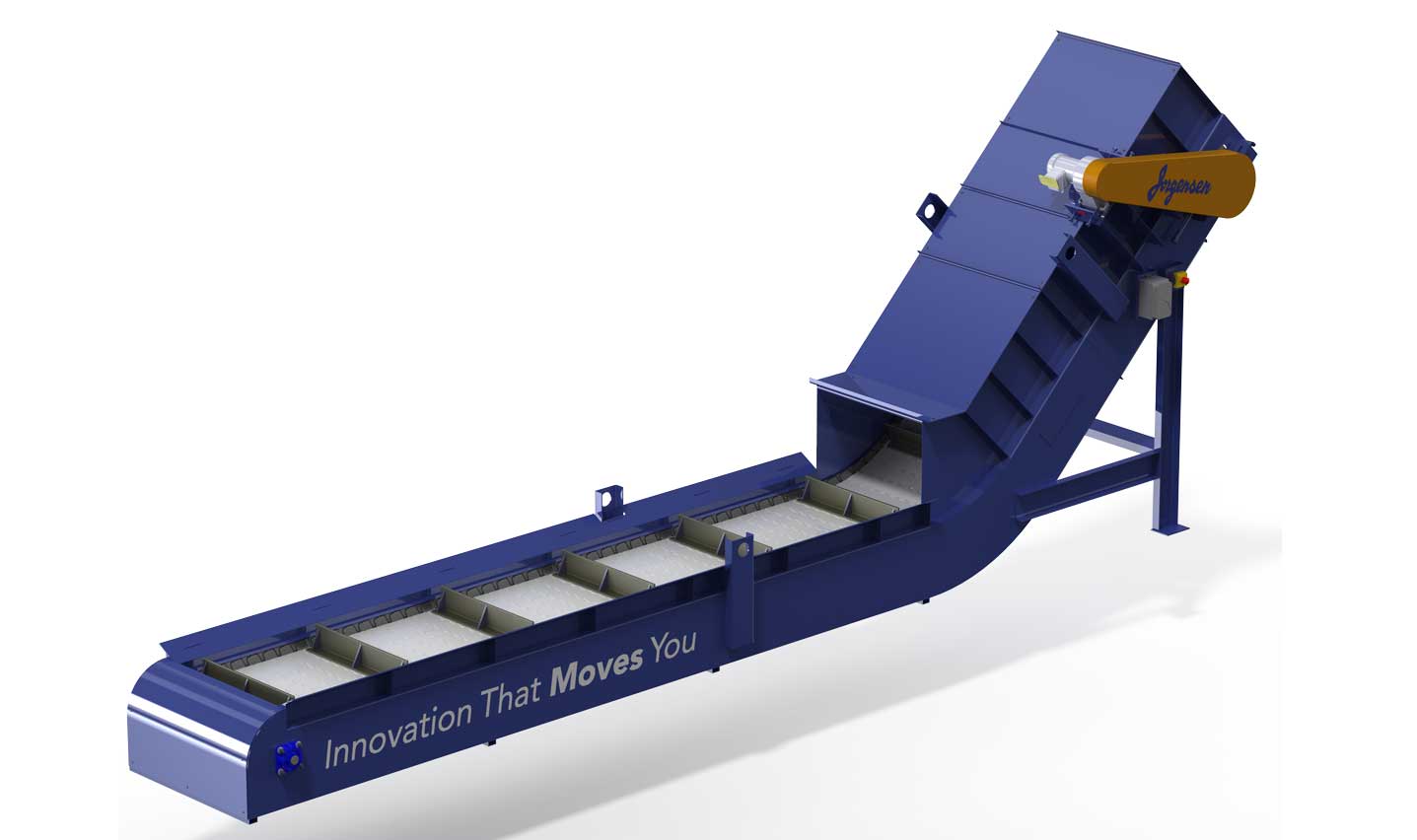

Jorgensen offers a complete line of engineered conveyor solutions for your casting application. We can provide a variety of belt types in a wide range of widths to meet your specific application. These conveyors can be used for handling parts of all temperatures and sizes and weights. If you’re dealing with heavy metal castings, you’ll need robust and heavy-duty hinged metal belt conveyors capable of handling the weight.

The type of conveyor chosen for a particular casting process depends on factors such as the material being cast, the size and weight of the castings, the layout of the casting facility, and any specific environmental conditions like temperature or humidity. Our steel belt conveyors move casting materials or products along a defined path. They are suitable for handling irregularly shaped or hot castings as they offer better durability and heat resistance. Magnetic conveyors use magnets to move ferrous castings or materials.

Our team can assist you with choosing the right conveyor for your application. Considerations of safety, efficiency, part quality and preventing downtime will be taken into account as Jorgensen sales engineers help choose the right conveyor for your casting application. As with all of our conveyors, Jorgensen offers a wide range of control and sensor technology to maximize the quality and productivity of your casting operation.

Contact us to learn how these and other Jorgensen product solutions are made for your application!